About us

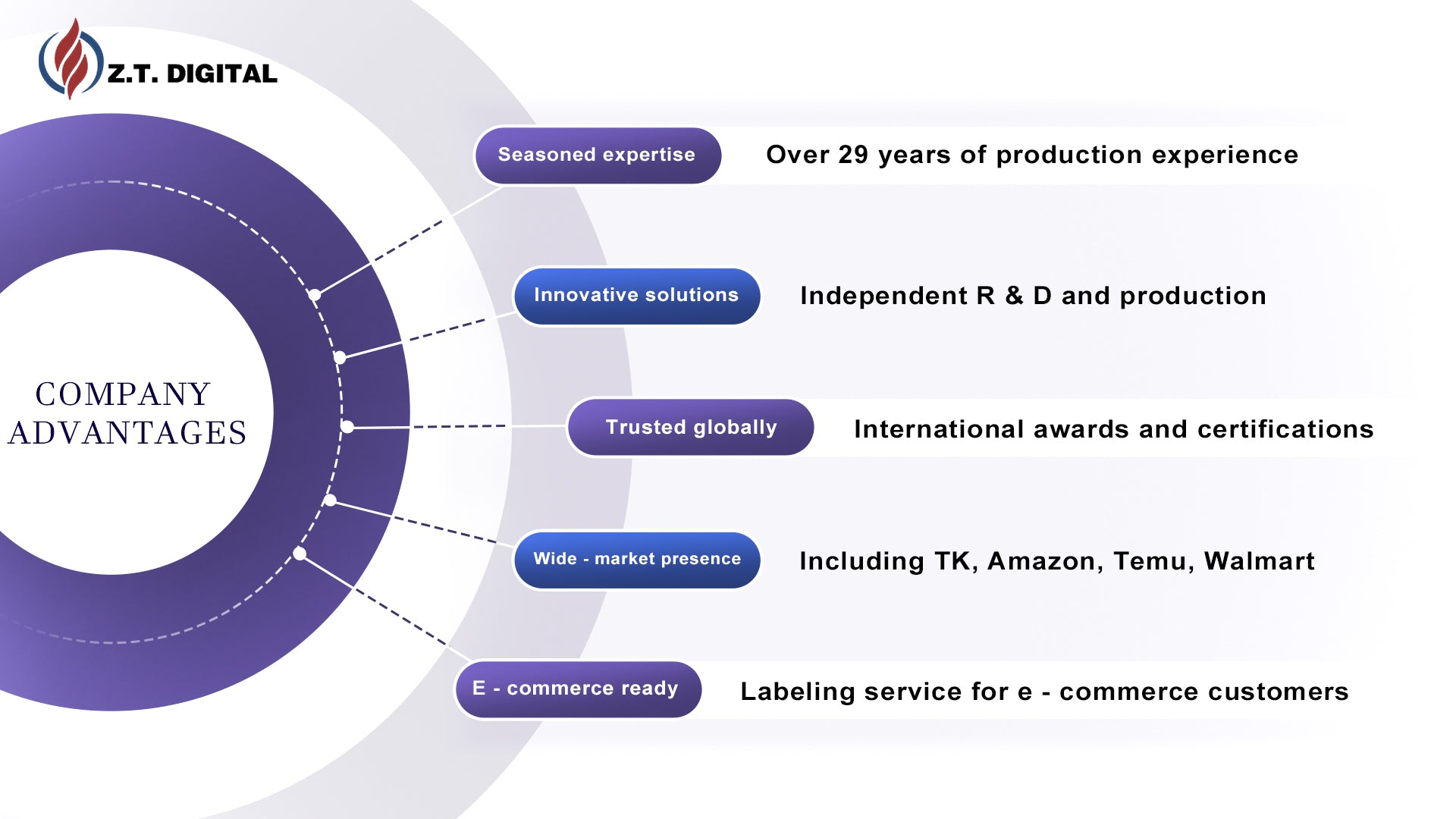

Shenzhen Zhongteng Digital Technology Co., Ltd. is a high - tech firm specializing in night vision device and related optical products, setting a high standard in the industry.We integrate R & D, production, and sales. Boasting multiple national patents for core tech, we've proven our optical expertise. Our high - tech team holds full independent IP rights, with unique tech edges in electronics, software, imaging, materials, and coating. This blend of skills positions us at the global forefront of high - tech product R & D and industrialization.Qur main focus is on daylight, low - light,and full - darkness night vision. Our products, sold worldwide,are used in outdoor sports, hunting, security, and law enforcement, ensuring clear vision in diverse situations. Thanks to top - notch quality and performance, we're among the world's leading night vision device makers, winning acclaim for our pre - sales, in - sales, and after - sales services.Our business philosophy centers on "integrity - based operation and win - win cooperation." We see quality as our lifeblood, service as our guide, tech as our support, talent as our foundation, and we stick to innovation and truth - seeking.Our goal is to lead the global low - light industry, Through non - stop innovation, we aim to expand human vision. We're committed to "'doing good, real, and earnest work" in R & D and customer service, fueling the progress of optical technology.

Featured products

-

3-inch Binocular Night Vision Goggles 600-Meter Viewing Distance With a Tactical Light Outdoor and Security Observation

Regular price $99.00 USDRegular priceUnit price / per$139.00 USDSale price $99.00 USDSale -

4" Ultra Screen Binoculars Night Vision Binoculars Digital Infrared 5X Zoom Hunting Accessories 3-in-1 Night Vision Device

Regular price $129.00 USDRegular priceUnit price / per$189.00 USDSale price $129.00 USDSale -

4K Built-in Magnify Display 3" Night Vision Goggles Binocular Telescope 100% Full Darkness 600Meters Night Vision Scope Goggles

Regular price $138.00 USDRegular priceUnit price / per$188.00 USDSale price $138.00 USDSale -

4K FHD Night Vision Binoculars With 5X Magnification 600 Meters Range Infrared Camera Easy to Carry ODM Customized Support

Regular price $69.00 USDRegular priceUnit price / per$109.00 USDSale price $69.00 USDSale -

4K Night Vision Goggles Binoculars IR 1968ft 64GB Tactical Light EPP Packaging & SCOPE for Air-Soft Games Nocturnal Fishing

Regular price $189.00 USDRegular priceUnit price / per$259.00 USDSale price $189.00 USDSale -

Helmet Night Vision Monocular 5X40 Night Vision Infrared IR Camera Digital Hunting Night Vision Scopes

Regular price $69.00 USDRegular priceUnit price / per$109.00 USDSale price $69.00 USDSale -

Light - Weighted Monocular Night Vision Spherical Night Lens with Tactical Light Suited for Spirited Outdoor Engagements

Regular price $118.00 USDRegular priceUnit price / per$148.00 USDSale price $118.00 USDSale -

New Arrivals Helmet Night Vision Binoculars OLED HD Screen CMOS 4K UHD Head Mounted InfraredNight Vision Goggles with 64GB

Regular price $189.00 USDRegular priceUnit price / per$259.00 USDSale price $189.00 USDSale

SMT Dust-Free Assembly Workshop

Cleanroom Environment & Facilities:

The enclosed space is equipped with an air purification system (HEPA filtration), anti-static epoxy flooring, and cleanroom-grade wall/ceiling panels to minimize particulate contamination.

Real-time monitoring systems display environmental data (e.g., temperature 22±2°C, humidity 50±5%), complying with ISO Class 8 (or higher) dust-free standards.

SMT Production Line:

Fully automated pick-and-place machines (e.g., Siemens, Yamaha) operate at high speed, with robotic arms precisely mounting miniature components like 0402/0201, followed by reflow soldering.

Neatly organized material racks hold reel-mounted ICs, resistors, capacitors, etc., with clear labeling reflecting lean management practices.

Personnel Protection & Operations:

Staff wear anti-static suits, gloves, hairnets, and masks, conducting quality inspections under microscopes or AOI equipment within designated work zones.

Some areas may include air showers or sticky mats to further control contamination sources.

Finished Product Packaging Line

Automated Packaging System

High-speed conveyors and robotic arms perform auto-boxing, sealing, labeling and palletizing

Integrated checkweighers and metal detectors ensure package integrity

Manual Inspection Station

QC inspectors conduct final visual checks under LED light tables

Barcode scanners verify traceability codes and packaging information

Packaging Material Management

Customized boxes/cushioning materials stored in smart racks by SKU

Variable data labels with logistics info printed by auto-labelers

Lean Production Layout

Anti-static epoxy flooring demarcates functional zones

Digital dashboards display real-time pass rates and line tempo

Production Line

Process-oriented Operation

Clearly divided process segments enable assembly line workflow

Conveyors/overhead systems connect all production stages

Human-Machine Collaboration

Operators performing assembly or inspection at workstations

Automated equipment handling repetitive high-precision tasks

Production Control

Digital displays showing real-time production data

Standardized work instructions ensure consistent quality

Featured products

-

3-inch Binocular Night Vision Goggles 600-Meter Viewing Distance With a Tactical Light Outdoor and Security Observation

Regular price $99.00 USDRegular priceUnit price / per$139.00 USDSale price $99.00 USDSale -

4" Ultra Screen Binoculars Night Vision Binoculars Digital Infrared 5X Zoom Hunting Accessories 3-in-1 Night Vision Device

Regular price $129.00 USDRegular priceUnit price / per$189.00 USDSale price $129.00 USDSale -

4K Built-in Magnify Display 3" Night Vision Goggles Binocular Telescope 100% Full Darkness 600Meters Night Vision Scope Goggles

Regular price $138.00 USDRegular priceUnit price / per$188.00 USDSale price $138.00 USDSale -

4K FHD Night Vision Binoculars With 5X Magnification 600 Meters Range Infrared Camera Easy to Carry ODM Customized Support

Regular price $69.00 USDRegular priceUnit price / per$109.00 USDSale price $69.00 USDSale -

4K Night Vision Goggles Binoculars IR 1968ft 64GB Tactical Light EPP Packaging & SCOPE for Air-Soft Games Nocturnal Fishing

Regular price $189.00 USDRegular priceUnit price / per$259.00 USDSale price $189.00 USDSale -

Helmet Night Vision Monocular 5X40 Night Vision Infrared IR Camera Digital Hunting Night Vision Scopes

Regular price $69.00 USDRegular priceUnit price / per$109.00 USDSale price $69.00 USDSale -

Light - Weighted Monocular Night Vision Spherical Night Lens with Tactical Light Suited for Spirited Outdoor Engagements

Regular price $118.00 USDRegular priceUnit price / per$148.00 USDSale price $118.00 USDSale -

New Arrivals Helmet Night Vision Binoculars OLED HD Screen CMOS 4K UHD Head Mounted InfraredNight Vision Goggles with 64GB

Regular price $189.00 USDRegular priceUnit price / per$259.00 USDSale price $189.00 USDSale